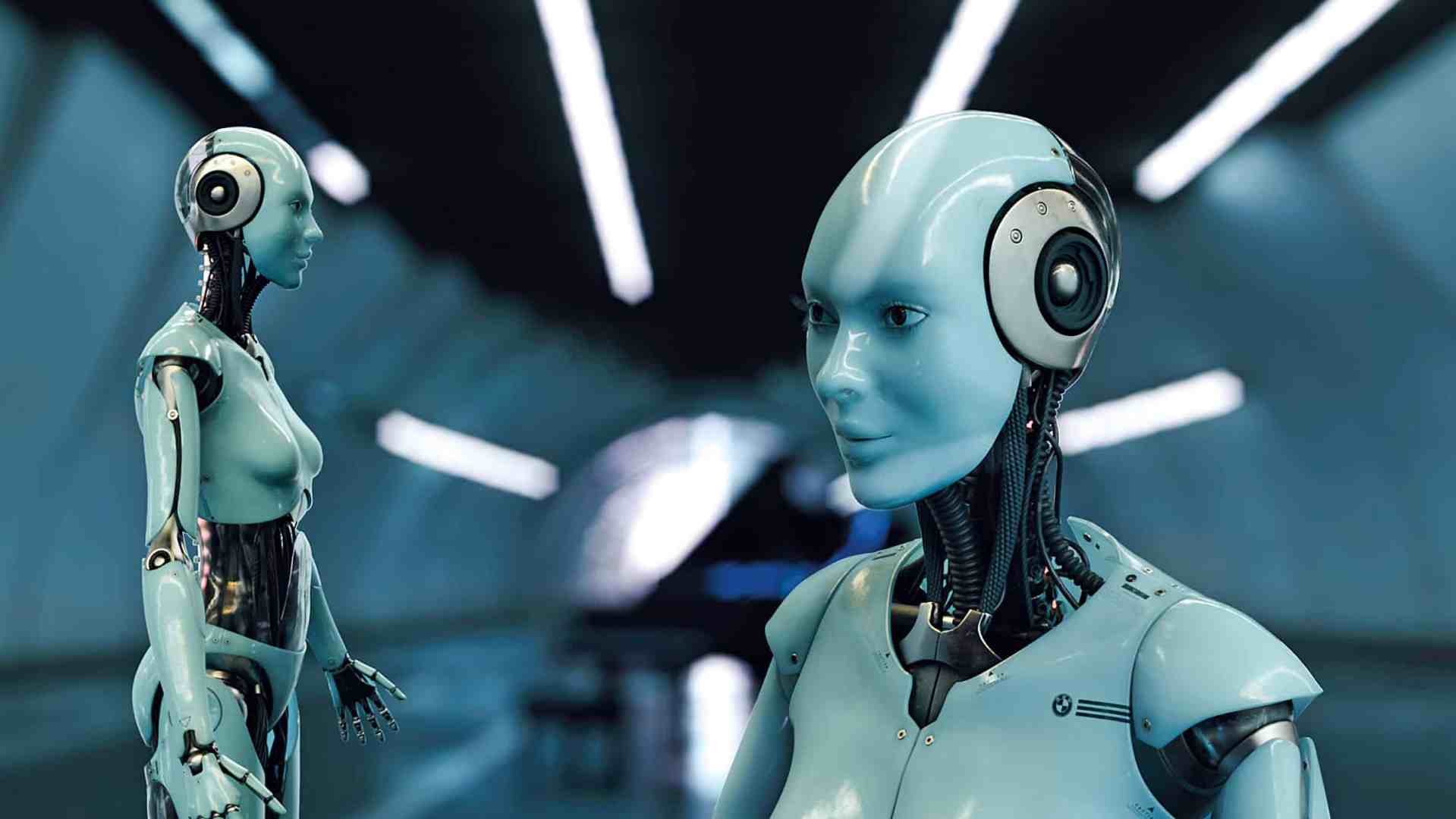

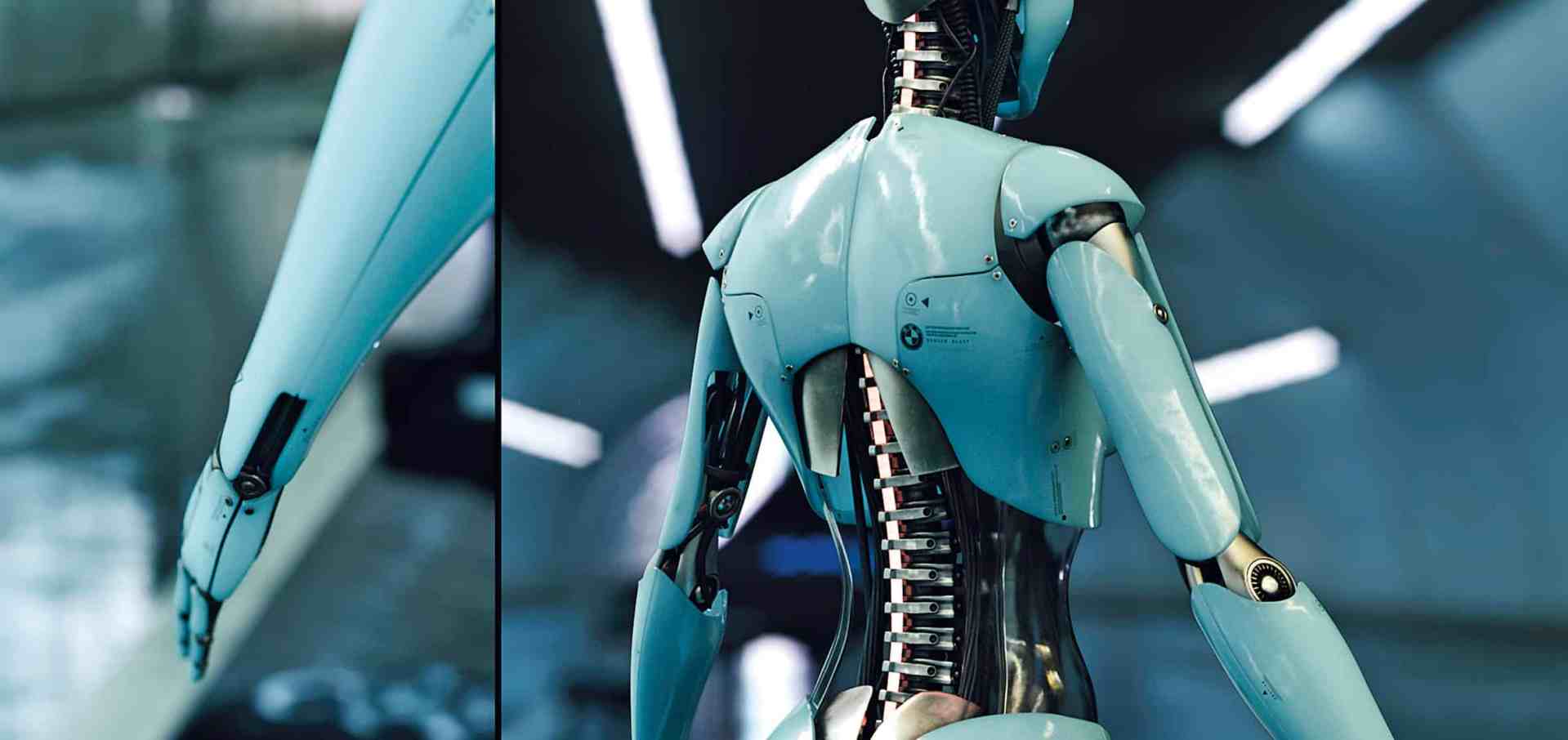

A robot walks towards a black-painted grand piano. Orchestral music begins and transforms the road tunnel into a stage. The robot begins to play the grand piano. Its movements are fluid, similar to those of a human being. Nevertheless, its mechanical construction is clearly visible. Transparent components in the back and neck area allow a glowing orange cable to shine through – it brings the robot to life and gives it energy. At the same time, the materials are reminiscent of components in modern vehicles, reflecting the future of car paintwork. I was able to accompany this film as Senior VFX Producer/Consultant – and this is how the project went.

by Dominic André Bitu

This advertising film for the automobile company BMW was produced by Hochkant Film GmbH & Co KG under the direction of Knut Burgdorf. The company brought Mackevision Medien Design GmbH from Stuttgart on board as VFX partner for the animation of the robot. Hochkant director Knut Burgdorf and Mackevision VFX supervisor Juri Stanossek had already successfully realised various projects together in the automotive sector. In spring 2016, this film idea was to be realised for BMW at short notice.

Phase 1: Filming

Filming for the advertising film took place in Los Angeles. A film team from Hochkant shot the film in a tunnel there. At the same time, Mackevision’s VFX team was already working on the design of the robot. During filming, a stand-in model took on the role of the future robot. A real actress made it possible to capture the movements of the later CG character precisely in the framing and scene lighting. Because the environment contains enough natural tracking makers (tunnel, road, wings), no separate markers were necessary. This meant that the director could specify the movements precisely, which shortened the downstream animation time.

To make it easier to read the body movements later, the stand-in model was filmed wearing a catsuit. “In this case, the downstream CG production requires less creative animation and more rotomation, which is much faster to execute. The original human movements are simply adapted to the digital robot and the result looks very real,” explains Juri Stanossek, VFX supervisor at Mackevision. The director instructed the actress precisely during filming and was thus able to control when the character sits down at the piano, when she raises her arms and starts playing, how she holds or turns her head and much more. Due to the tight production schedule, this simple production method meant that the coordination loops with the director could be kept short.

In order to be able to edit the backplates digitally later, it was important to document the environment visually on location. HDRI photos were therefore taken of all sections, corners and angles of the tunnel. They provide comprehensive information about the lighting conditions, as this is the only way to reproduce the lighting situation digitally on a one-to-one basis. This was particularly important as the robot’s shiny materials needed to have realistic reflections.

Phase 2: Creation of the robot

Even before filming began, Mackevision received a detailed briefing from the director on how the robot should look. Its look should symbolise future technologies and innovations, but at the same time convey a familiar, humanoid feeling in order to briefly transport the viewer into a harmonious vision of the future. Based on the director’s brief, concept art and a collection of mood images were created to quickly visualise the character.

“The character had to be likeable, not too crazy, but still appeal to the future,” explains Stanossek. The “detailing” of the CG character was therefore important and the robot also had to fit in with the customer and their corporate communication and visual language.

Once the design had been approved by the customer, the next step was to model the robot. For example, the look and shape of the face as well as the materiality were adapted and fine-tuned. We tested real materials such as plastic, porcelain and silicone. Good communication, precise instructions from the director and close coordination with the customer were necessary here in order to jointly develop the different variants into the perfect robot.

“We only had just over two weeks for the complete production of the CG character, from the first draft to the finalised and rigged robot. The visual demands were extremely high, which we are used to from our daily work on car productions or feature films – we didn’t have to adapt our pipeline, which is designed for commercials and feature films. And with Nuke, 3ds Max, Maya, V-Ray and 3D Equaliser, we are flexible and have robust tools in our hands,” notes VFX producer Marina Winter, who was responsible for producing the VFX production and, among other things, for coordinating and liaising with Hochkant Film as well as time management.

A whole series of questions had to be clarified. How transparent should the robot be in the end? What materials should be visible? Plastic, porcelain or metal – with a matt or glossy finish? Where should it be transparent and where should it be more opaque? Senior artist David Anastacio assigned all these material properties to the robot’s components. Attention was also paid to the mechanics. The elbows, spine and joints had to function as if the robot had actually been built in reality. Accordingly, all exterior parts of the robot, but also the only partially visible interior parts, had to be rigged and made animatable.

The underlying rig was relatively simple, as it didn’t have to be able to do much – the robot was excellently prepared by the precise set work. We then animated with Maya and exported the animation to 3ds Max with Alembic. No other additional tools were used. The HDRIs were used for the 3D reconstruction of the tunnel.

Phase 3: Animation of the robot (post-production)

While the assets for the CG character were being created, the unedited plates were being edited in parallel. Two weeks after filming, Mackevision received the final edited versions for shot production. The individual shots were entered by the Mackevision editorial team under the direction of Tobias Pfeiffer and synchronised with the parallel editing with Hochkant Film. The shots then went into the matchmove, which the so-called “Parallaxman” did with a high degree of speed and perfection – we outsource this step because we don’t have a matchmove artist internally.

The environment – i.e. the tunnel – was built as a low-poly environment and textured using the photos from the set. The character was then textured and shaded. The robot was then animated – again by Maya using Alembic in 3ds Max.

The gait, gaze and piano playing of the stand-in actress were transferred one-to-one to the robot. The piano also had to be recreated in 3D in order to correctly calculate the shadows that the robot casts on the keys, for example, as well as the movements of the keys themselves in space. Once the animation had been approved by the customer, the project went into rendering. The rendering was done in V-Ray. A very high “A-over-B” quality was aimed for and achieved in order to keep the compositing time as short as possible. “In the final step, our compositing artist worked on the photorealistic integration of the robot,” says Stanossek.

After just 15 days, the final robot shots were delivered to Hochkant Film for integration into the BMW advertising film. “This very short overall processing time from shooting to delivery of the VFX shots was only possible thanks to close hand-in-hand working and fast approval processes and coordination,” concludes Stanossek.

The making-of video for the advertising film can be seen on Vimeo bit.ly/BMW_Roboter_Mackevision