People are drinking beer again. On certain days, the first rays of sunshine tempt us to enjoy a beer under a blue sky. Fittingly, the pilsner brand Warsteiner is celebrating its 260th birthday with an advertising campaign designed by nhb. This is not the first film that nhb and the Kolle Rebbe agency have produced for the Warsteiner brewery, but the Warsteiner anniversary advert is the first time that the studio has also created the bottles in 3D.

You may have already seen the advert during the commercial break: The Warsteiner bottles dance their own choreography, beer bubbles, crown caps fly and at the end the beer bottles form into the number 260.

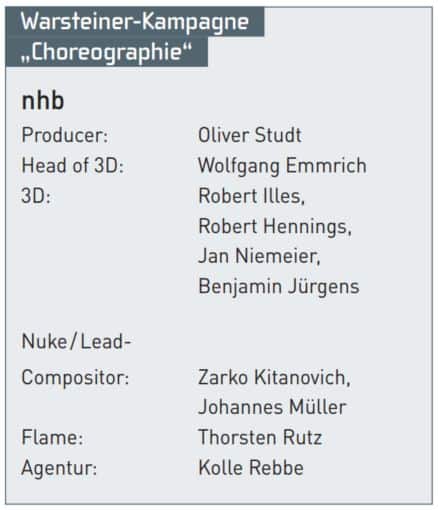

The anniversary crown cork campaign makes drinking beer worthwhile again, because those who have the right cap on the bottle can win a Mercedes, city breaks or an iPhone, among other things. For the “Choreography” spot, nhb visualised the bottles, the fluid simulation including foam and air bubbles as well as the winning products. The collaboration between Warsteiner, nhb and the agency Kolle Rebbe from Hamburg began with a cinema spot in 2007, and from 2008 the studio covered the entire Warsteiner advertising programme with TV, cinema and radio spots. For previous adverts, the bottles were filmed with a phantom camera and a motion control rig. During filming, however, there are restrictions regarding the length of camera movements as well as the size and number of image elements, which nhb was able to overcome with a complete CG realisation. nhb had already shown Warsteiner how efficiently the VFX department can work for the 2012 European Football Championship campaign and recreated a football stadium, including the pitch and spectators, in 3D. As the proportion of 3D in commercials has generally increased and Warsteiner was very pleased with nhb’s previous 3D looks, the brewery trusted the studio to create a complete 3D visualisation for this film. Digital Production spoke to Head of 3D Wolfgang Emmrich about the beer project.

DP: What are the advantages of a complete 3D realisation compared to a real shoot with a phantom camera?

Wolfgang Emmrich: The most important advantage is that you can completely override physics. Working in 3D offers the greatest possible freedom, there is no limit or end to shooting. In 3D, you can depict extreme camera movements and lens changes that would not be possible in real life. You have full control over the image, movement and lighting and can always change or generate new versions.

DP: Which production method was ultimately more cost-effective?

Wolfgang Emmrich: It’s hard to say, especially the last two big jobs we did for Warsteiner can hardly be compared with each other. Each production method certainly has its advantages and disadvantages. With this storyboard, however, a complete CG realisation made more sense and certainly saved costs.

DP: What specifications did you receive from the client for the look of the advert?

Wolfgang Emmrich: The specifications for the look were the key visuals from the Warsteiner print campaign on the one hand, but also the real shot pack shot from the European Championship Warsteiner film, which we retouched extensively on the flame in summer 2012 and sent through the colour correction process. Basically, the look that we developed from last year’s project.

DP: What other specifications did you receive from Warsteiner?

Wolfgang Emmrich: The briefing stipulated that the bottles, the beer and the whole film should look as natural as possible and not at all computer-generated. The beer had to look refreshing, tangy and delicious. DP: What was your workflow for the project? Wolfgang Emmrich: First we visualised the storyboard with wireframes so that we could develop a feeling for the timing in the moving image. The 3D then worked with Softimage, Realflow and Maya. The compositing was done in Nuke and the finalisation, creation of the titles and mastering as well as the customer approval took place at Flame. We rendered with Arnold and V-Ray as well as the nhb render farm with two THZs.

DP: What challenges did you face?

Wolfgang Emmrich: The most important thing for the entire project was that the liquids and the bottles looked absolutely natural at all times. That was a particular challenge when relighting and grading in Nuke.

DP: How long did the process take overall?

Wolfgang Emmrich: Including all the coordination and development processes, we worked on the advert for around eight weeks in total. Our VFX department in Düsseldorf also took on important work in order to keep to the specified timing.

DP: Why did nhb Düsseldorf create the Mercedes? Does this branch specialise in car models?

Wolfgang Emmrich: No, we make car models at all three nhb locations. We have a high-performance network, which benefits us with such extensive jobs. Thanks to our server-based workflows, we can utilise our resources at any time, regardless of location. This means that if we need capacity in Hamburg, we can provide immediate support from Düsseldorf or Berlin. In this case, we gave all the work on the car model to Düsseldorf. It was so easy to organise perfectly. The Mercedes was delivered as a CAD model.

DP: What tools did you use to create the swirling beer jet?

Wolfgang Emmrich: Producing a beer jet like this using fluid simulation, including foam formation and air bubbles, is one of the most difficult tasks in the field of digital image creation. We use the Realflow and Maya fluid simulation software for this kind of thing, which we have also used for previous Warsteiner projects.

DP: How did you go about colour grading?

Wolfgang Emmrich: This job required lighting design rather than colour grading. The desired look had already been defined beforehand and was developed in 3D and Nuke according to the specifications from the print campaign and the 2012 packshot. This meant that no colour grading on Lustre or Baselight was necessary afterwards.

DP: What are your next projects at nhb?

Wolfgang Emmrich: We are currently very busy in all branches and many projects are in the pipeline, across all disciplines from beauty to food. Some of our work is also being submitted by agencies to important festivals, such as the ADC in Hamburg and the Cannes Lions. You can look forward to that. We always present the latest projects on our website http://www.nhb.de.

DP: How do you deal with the thirst for beer when you have to look at refreshing beer bottles as a project every day?

Wolfgang Emmrich: Now that you mention it… (chuckle … chuckle … chuckle…)